- today

- perm_identity Rastamax

- label Hardware

- favorite 8 likes

- remove_red_eye 28047 views

- comment 0 comments

How to preserve your LED lighting beyond its announced lifespan?

LED grow lights are expensive to purchase, and manufacturers promise a significantly long lifespan. What can we do to put the odds on our side, and benefit as long as possible from our recent investment?

LM certification and lifespan projections

With the appearance of LEDs and their democratization in all types of lighting solutions since the beginning of 2000, the IES (Illuminating Engineering Society of North America) was forced to standardize the measurement and quantification techniques of the different quantities physics associated with this technology. In this way all manufacturers present their products characterized by consistent and revealing values, which is a definite advantage for the consumer. The LM80 standard is a perfect example.

LM80 kesako?

This certification actually corresponds to a way of making an estimate of the long-term loss of luminous flux for a chip or an array of LED chips. It is therefore carried out by the manufacturers of light-emitting diodes (LED), and it is the manufacturers of horticultural LED panels who will use this estimate to extrapolate these characteristics to their armature.

The procedure to follow is a series of luminous flux measurements over a period of 6,000 to 10,000 hours, with assemblies stabilized in temperature at 55°C, 85°C and 105°Cfor each diode model. Then with well-honed mathematical models we can extrapolate the wear of the diodes over longer periods.

Operating temperature and lifespan

What emerges from any LM80 measurement is a clear flow loss in the medium-long term for the highest temperatures. The challenge for armature manufacturers is now to design a luminaire capable of correctly dissipating the heat released by the diodes in order to maximize the maintenance of the latter's luminous flux. When a prototype is tested, its stable operating temperature is determined, and with the latter, we can make the link with the LM80 certification of the diode manufacturer. This exercise of transitioning from predictions for diodes to predictions for a complete armature is called TM21.

We can see directly that the goal is now to favor an armature which will allow the best possible dissipation, and for reasons of reliability, power consumption, comfort, and ease, most manufacturers are moving towards passive dissipation . This is not a bad thing when it is well designed. In fact, the simple heating of small radiant fins can create an air convection movement within them and therefore result in a relatively low temperature thermal equilibrium. The value of this temperature will necessarily depend on the ambient temperature, the quantity of aluminum used in the cooling system, and the electric current sent through the diodes.

Let us note, however, that other criteria may impact the maintenance of the flow of the armature in the long term, such as for example a potential tarnishing of the optics (if there is one) and/or protective glass, or even a potential sulfurization of the diodes linked to contact with certain phytosanitary agents or fertilizers.

Aluminium galore!

If the trend is not towards watercooling, there is a reason!

Indeed, a passive system will always be morereliable than any active system, especially when lifespans of several tens of thousands of years are expected. hours. And with the constant increase in the price of metals it is obvious that a good component of the price of a well-designed LED fixture is that of the aluminum that it is made of. All that remains is to put the right amount of aluminum in the right place!

Another advantage, and not the least, of passive systems lies in the fact that it is up to us to activate it...

A little experimentthis

Description

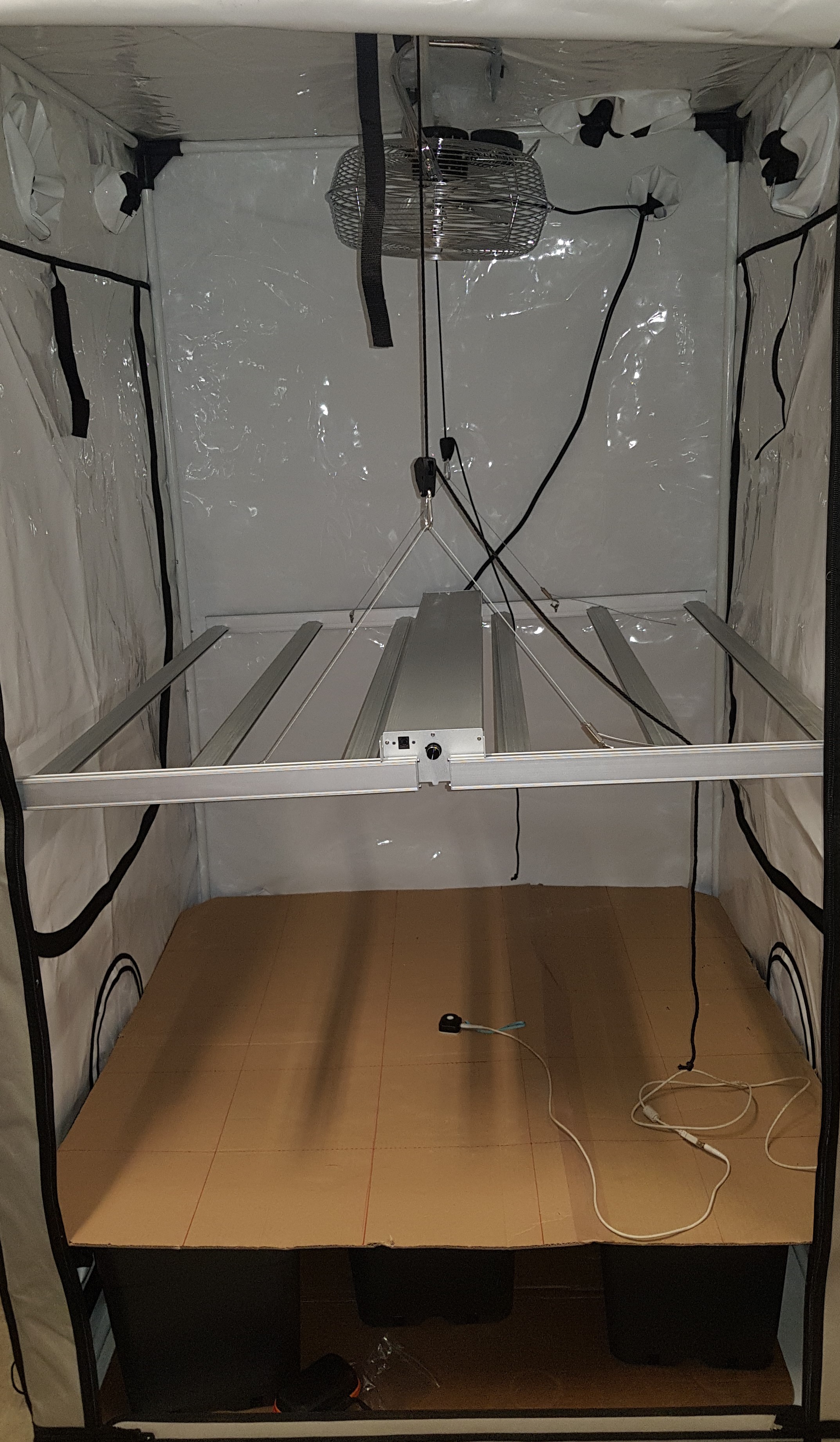

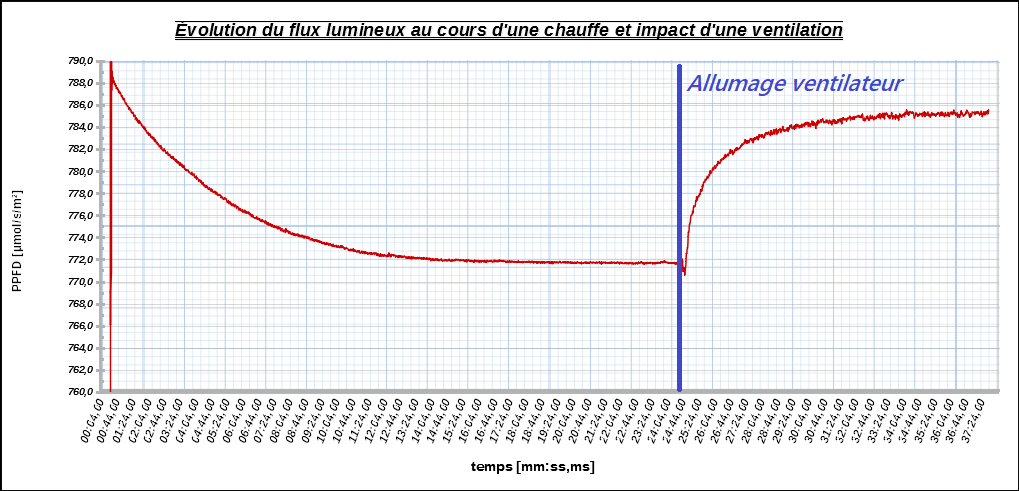

The idea is as follows: since a cooler lamp maintains its luminous flux better over the years, we will try to lower the temperature of the thermal equilibrium in operation. To do this, we equipped a growing tent with a Hortimol MG6 light fixture, topped with a fan oriented from top to bottom, towards the frame. A continuous measurement of the photosynthetic flux density was carried out at the center of the illuminated surface 60 cm from the luminaire, during the lamp heating cycle. Once the PPFD measurement stabilized (when the thermal equilibrium temperature was reached), we turned on the fan located above the lamp and observed a direct change in the thermal equilibrium.

Interpretation

The first observation is that, for this model, in this configuration, we observe a difference of 2.2% in direct luminosity between on the one hand the flux when the lamp is at ambient temperature (i.e. when it has just been lit and it has not yet heated) and on the other hand the flow when thermal equilibrium is reached.

A second observation is the efficiency of the fan, the lamp cooled faster than it heated and the new difference is only 0.5%. This tells us that the temperature of the armature has actually dropped, the diodes will be better preserved.

Also note that if this assembly promotes a lower temperature at the level of the frame it is because it promotes the exchange of heat between the luminaire and the environment . We must therefore expect slightly warmer climatic conditions, but still less than in HPS.

In conclusion

What dictates whether or not the luminous flux is maintained over the long term is mainly the operating temperature of the diodes. It is therefore interesting to try to minimize the latter, for example using a fan oriented towards the lamp. If this technique has been shown to be effective in preserving your luminaire, it is also necessary to take into account a slight increase in instantaneous luminous flux, as well as a slight increase in ambient temperatures given the heat exchange put in place.

Related products

Hortimol MG6 Led 480w FSM+ 2.8μmol/J

480W, 2.8 µmol/J, 1344 µmol/s

Fanless Design, IP65 Waterproof, 0-10V Dimming

Full spectrum (FSM), Osram LEDs, Sunribio IR, LM-80

Comments (0)